In the oil and gas industry, extensive lengths of connected pipes extract and transport substances across long distances. Threaded together, this series of adjoined pipes forms a drill string. These threaded connections between drill strings and pipe sections must maintain exceptional strength and durability, especially given the harsh conditions of these applications. Using cold root rolling (CRR) techniques, industry professionals can enhance these connections.

CRR involves the use of tools and surface treatments to reduce material stress, strengthen crystalline structure, and improve the definition of threaded connections. After a thorough explanation of the various cold rolling processes available, this post provides an in-depth analysis of the advantages of cold root rolling specifically in oil and gas applications.

Cold Root Rolling Processes

Categorized in two types, CRR processes include burnishing and cold root rolling. Each process depends upon different techniques and principles to enhance the strength of threaded connections.

Burnishing

During the burnishing process, a wheel or roller applies pressure to the surface of a steel alloy in order to compress the surface layer. The compressive force causes the metal to flow, allowing the material to balance residual stress from prior manufacturing processes. Burnished components exhibit a smooth surface finish, improved surface hardness, and greater durability.

Cold Root Rolling

A third process, cold root rolling, focuses specifically on burnishing the root radius of a cut thread. Using specialized equipment, pressure applied to the thread’s root radius via a roller or ball displaces the threaded material. This deformation minimizes surface tension and allows a more durable and reliable threaded surface.

Cold Root Rolling for Oil & Gas

The CRR process offers a variety of benefits for both on and offshore applications in the oil and gas industry.

Improved Strength

Using CRR, rotary-shouldered connections grow stronger because of a hardening effect. As a component hardens, uniform steel grain structures experience compression and displacement, thereby increasing the overall service life of threaded connections.

Lower Thread Root Stress

CRR significantly reduces or eliminates surface stress through the use of compressive force. With less stress at the root of the thread, connections can withstand greater levels of tensile stress during operations without cracking or breaking.

Reduced Chemical Erosion

By smoothing the surface of a previously cut thread at the root, cold rolling eliminates any scratches and imperfections. This uniform and flawless surface not only strengthens and reduces tensile stress on the component, but it also resists potential chemical erosion.

In-House Work

By incorporating CRR equipment into existing fabrication processes, larger companies can keep work in-house. With streamlined manufacturing and production, the workforce stays employed and engaged throughout the operation, improving individual business and the overall economy of the market.

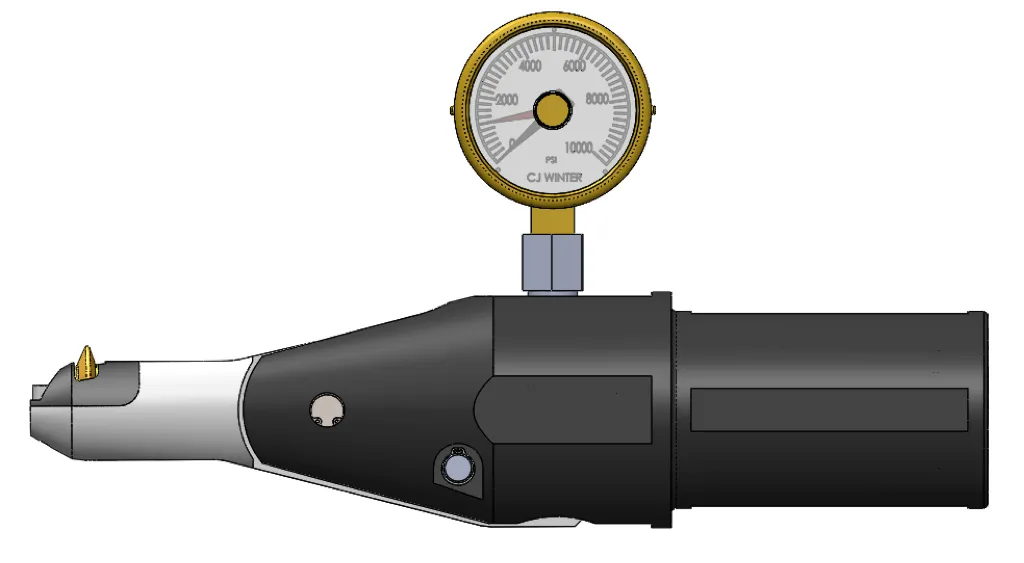

Exceptional Cold Root Rolling Solutions From CJWinter

As experts in cold root rolling, CJWinter proudly provides top-quality tooling and equipment. Our tooling line for CRR rotary-shouldered connections can be integrated into any system using a CNC lathe. Using our CRR tools, the strength and durability of your threaded connections improve without sacrificing process speed and efficiency.

Our patented line of tooling solutions offers a wide range of unique benefits for manufacturing processes:

- Every tool is self-contained. It is not necessary to connect to an outside power source in order to pressurize the roller piston.

- Every tool has an internal accumulator. Internal accumulators allow for rolling the thread under full pressure to the end.

- Every tool synchronizes hydraulic pressure and roller force. This synchronization allows the thread to be rolled accurately without the need for conversion.

- Every tool uses CJWinter EPL cold rolling dies. Our patented EPL dies eliminate the need for visual verification because their design ensures they load correctly the first time.

For threaded connections, the advantages of CRR far outweigh the cost of equipment and integration—especially for high-pressure, low-maintenance applications in the petroleum industry, where connection strength and reliability are a must. In the long run, the reduction in repairs and replacements will pay for the initial investment.

Contact CJWinter today to learn how you can integrate cold root rolling into your operations.