Cold Root Rolling is the process of burnishing the root radius of a previously cut thread, in a Rotary Shouldered Connection.

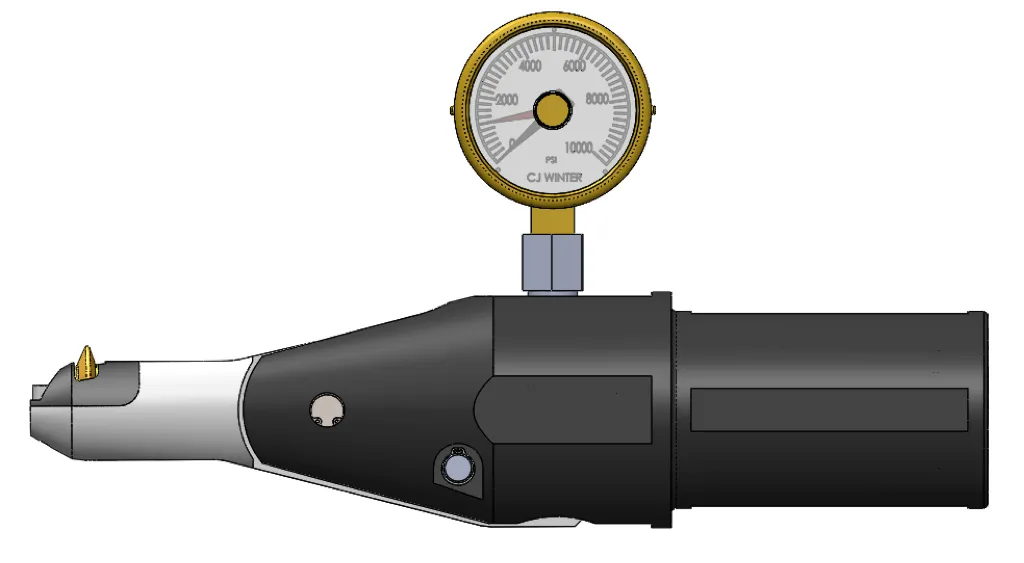

A hardened roll, similar in profile to the thread being manufactured, is placed in contact with the root radius of the tapered thread, and pressure is applied to force the roller to penetrate into the cut surface of the root radius, displacing and cold-forming the thread material.

This deformation cold-works the material, imparting an improved surface finish and compacts and displaces the grains of the root material.

Industry experience with the cold root rolling process has suggested an increase in fatigue life of 3 to 5 times over similar un-treated connections under the same working environment.

Some studies have noted laboratory results of up to 27 times better life attributable directly to cold root rolling process.

For almost 60 years, CJWinter has been an industry leader in supplying thread rolls and thread rolling tools globally.

CJWinter has used that experience to design tools specifically for Rotary Shouldered Connections in the Petroleum Industry.

We believe this is the only self-contained, commercially available tool that will cold root roll threads compliant with ANSI/API Specification 7.2:2008 and ISO 10424-2:2007, in accordance with NS-1 cold root rolling procedures, and DS-1 Third Edition, Volume 3.33.6.

Our in-house engineering staff is always available to assist with any technical manufacturing situation. Contact us today to request a compliance consultation with our engineering staff.

DOWNLOAD OUR FREE INFORMATIONAL RESOURCES

knowledge base

learn more from our blog

Cold Root Rolling for Oil & Gas

In the oil and gas industry, extensive lengths of connected pipes extract and transport substances

Why CJWInter Is the Better Choice for Cold Root Rolling

In high-pressure, high-saturation, and/or high-corrosion environments, the wear and tear of pipeline components is inevitable.

Cold Root Rolling for Better ROI

Your drill string is your lifeline. It’s a critical component of your business and it