Cold Root Rolling for Oil & Gas

In the oil and gas industry, extensive lengths of connected pipes extract and transport substances

• SRG (Stress Relief Groove) on Rotary Shouldered Connections

• Elevator Groove

• Slip Groove

• Slip & Elevator Groove

• Railroad

• Automotive

• Aerospace

• Wind Energy

• 11073-A-125-LH45-SA

• 11073-A-125-RH45-SA

• 11073-A-125-STR-SA

• 11073-A-150D-STR-SA

11073-A-125 series has a 1.25” square shank

11073-A-150D series has a 1.50” Ø shank

All burnishing wheels used on tools are 3.00” OD x .615” wide x .626” ID

Optional shank sizes are available upon request

Special features include:

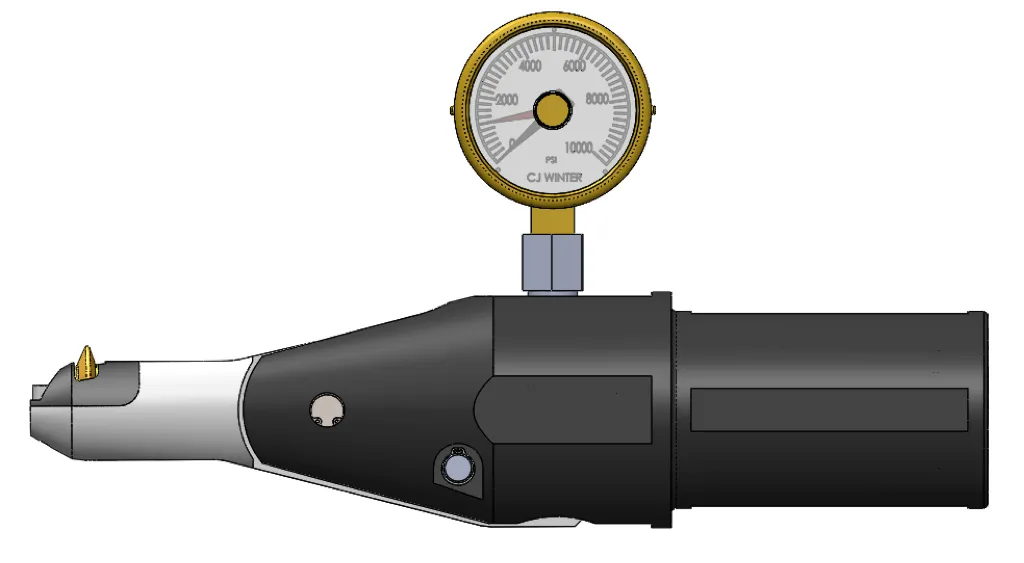

• Self-contained: All you need is a socket wrench to pressurize the roller piston

• Tool comes with NIST traceable certified gage

• Pressure ratio is 1:1 – the tool requires no conversion between the values of hydraulic pressure and roller force

• Liquid-filled pressure gauge: Values can be observed after the cycle is complete

• Easy compatibility: CJWinter tooling for burnishing is compatible with any CNC or manual lathe

Cold Roll Burnishing is often an OEM requirement of a particular component.

For the end user of highly stressed, fatigue-prone components, cold roll burnishing is also a money saving process. For example, in the oilfield industry, cold rolling can drastically increase the fatigue life of each rotary shouldered connection in a typical drill string. It can also reduce frequency of repairing connections in the field, and for having to fish for down-hole failures of the drill string. The estimates that the cost of a single down-hole failure can surpass 1 million dollars.

In the rail industry, a recent report by the US DOT estimates the cost of the average train derailment at 22.5 million dollars. There were 19 derailments in the United States attribute to broken axles / wheel sets between 2011 and 2014, the yearly costs are staggering. Cold roll burnishing reduces the likelihood of fatigue failures in critical-to-function parts.

Our 60+ years of industry experience in thread rolls and thread rolling tools enabled the unique design for the 11073 Series, as well as the entire family of cold rolling tools that CJWinter has engineered for the petroleum industry’s rotary shouldered connections.

The in-house engineering staff at CJWinter is always available to help with technical manufacturing situations, and to answer any of your questions.

Contact our team today for more information.

In the oil and gas industry, extensive lengths of connected pipes extract and transport substances

In high-pressure, high-saturation, and/or high-corrosion environments, the wear and tear of pipeline components is inevitable.

Your drill string is your lifeline. It’s a critical component of your business and it