Table of Contents

ToggleCJWinter rounded up a few emerging industry trends gathered while attending this year’s 2015 Houstex Convention, which featured hundreds of exhibitors highlighting the latest manufacturing technologies.

1. Opportunity for Added Value in Atypical Applications of CRR

Cold Root Rolled (CRR) connections have primarily been used in offshore down-hole drilling in instances where pipes are not supported or insulated by shale, but CRR connections provide added value for onshore applications. The same features and benefits apply, and early adopters with onshore applications can benefit from an added competitive edge.

2. There’s No Time for Downtime

CRR can save hundreds of thousands of dollars. By cold rolling a rotary shouldered connection, companies can safeguard against joint failure, improve fatigue life, and reduce the need for costly repair in the field.

Moreover, it only takes seconds to index CRR tools to begin the Cold Rolling process. By extending the lifecycles of connections from 3 to 25 times, this process offers a tremendous time and fiscal savings for companies drilling in deep water or onshore.

3. CRR Tools Improve Workplace Safety

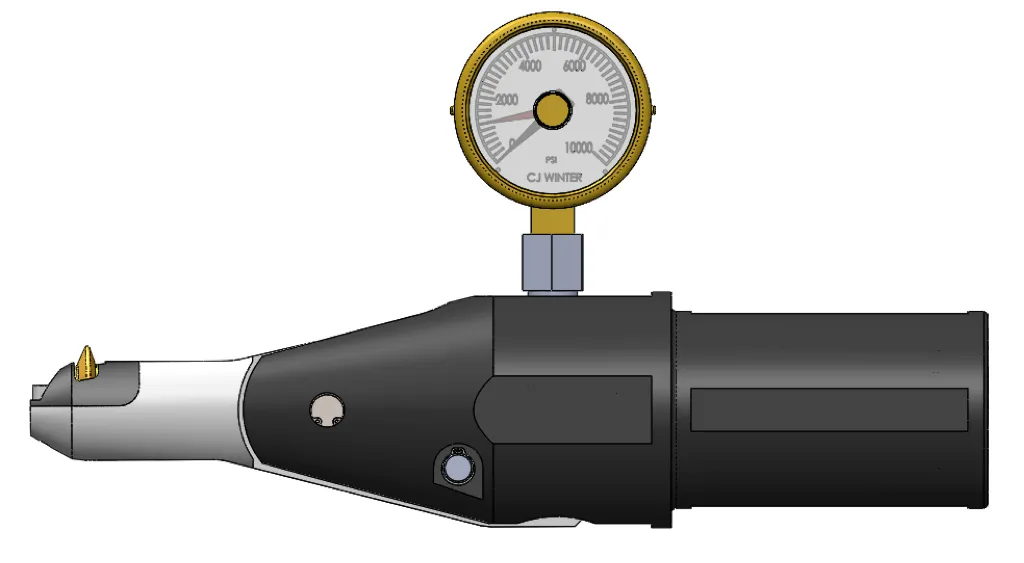

Safety is built in — a self-contained hydraulic tool like CJWinter’s is a prime choice for the CRR process because it doesn’t require additional materials to operate. Unlike competitors, CJWinter’s CRR tools do not require hoists to attach to the lathe. This reduces instances of user error and prevents simple mistakes which could have costly consequences.

4. Bring Work in House or Improve Vendor Partnerships

For larger companies that can afford to scale up staff and bring work in-house, this keeps your workforce employed. For medium to small companies that outsource this skill, it ensures work is completed efficiently and cost-effectively to a vital manufacturing standard.

5. CRR Tools Brace Your Team for Change on the Horizon

Many companies are currently cutting API threads and not completing the secondary process of Cold Rolling until it is required. Cold Root Rolling is an added value that saves time and money later on. If Cold Root Rolling becomes a standard, companies that implement the process now will be ahead of the curve and ready to work, eliminating any ramp-up time or learning curve.

CJWinter has been an industry leader in supplying thread rolls and thread rolling tools globally for almost 60 years. For more information about cold root rolling and the services we offer, visit our education center.