How Cold Root Rolling Enhances Strength & Service Life of Rotary Joint Connections

As the benefits of Cold Root Rolling become increasingly well-known throughout the Oil and Gas industry, it’s important to understand the reasons for the success of this innovative tool.

The process itself is quite simple; however, the enhancements to the life of Rotary Shouldered Connections — combined with a tool design that allows for use on a wide range of systems — makes the benefits of using root rolling tools hard to ignore.

Fatigue Life

Cold Root Rolling saves money by increasing the fatigue life of each rotary-shouldered connection. It creates a higher-strength connection that reduces the necessity and frequency of field repairs.

This minimizes costly down-hole failures and helps to increase overall operational efficiency.

Burnishing

The Cold Root Rolling process burnishes the root of a previously cut thread in a Rotary Shouldered Connection. By cold-working the material, scratches and imperfections on the thread profile are compacted into a more uniform surface, reducing stress, corrosion, and improving strength.

Scratches

Scratches are prime locations for chemical erosion on a thread because they are jagged and porous and can attract and hold corrosive chemicals common in a drill string environment. The Cold Root Rolling process flattens scratches and imperfections left by threading leaving corrosives no place to take hold.

Hardening Effect

Root rolling a threaded connection is a cold working process that has a hardening effect on the surface material. It displaces the structure of the steel grain from one that is uniform to one that has many dislocations.

These dislocations act like a web to prevent further deformation when the tool is in use. This resistance also prevents cracks from developing into larger structural flaws. Lab studies have shown that cold rolled joints present significantly lower crack length and depth or CAR (Crack Aspect Ratio).

Easy Integration and Implementation of Cold Root Rolling Tools

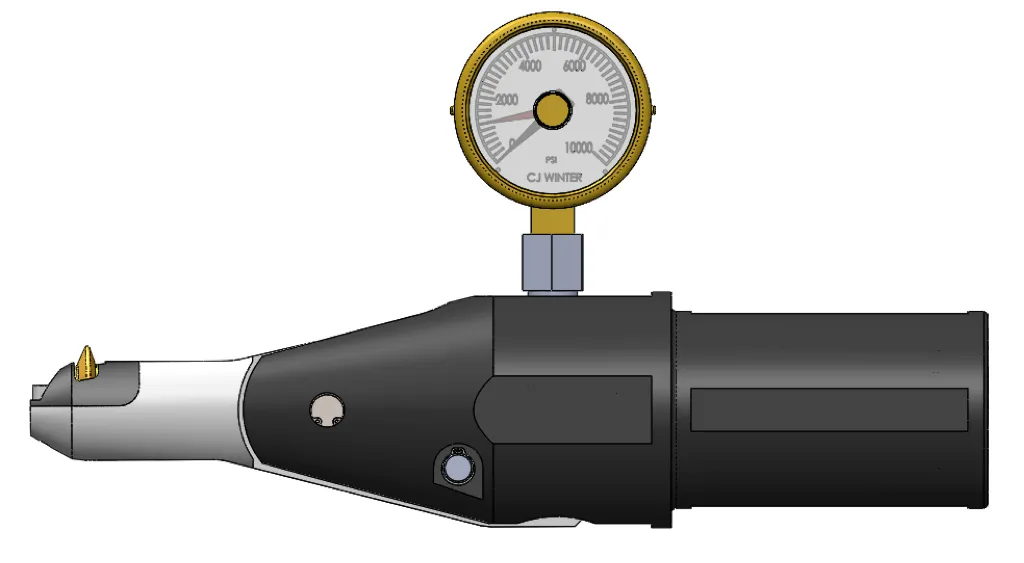

When it comes to implementation, all Cold Root Rolling tools are not created equal. CJWinter Cold Root Rolling tools are engineered to provide maximum value and versatility. They integrate easily with Mazak, Fanuc, and Weiler programming, and feature an asymmetric hub system (one side is larger than the other).

This makes loading the tool backward impossible. The tool also features a 1:1 pressure ratio that clearly converts PSI to pounds of force enhancing safety, and making employee training easier.

To learn more about how CJWinter Cold Rolling Tools can add value to your rotary joints or complete details on programming and machine integration, download our free informational guide.

Access Our Informational Guide