An inside look at how clients are using CJWinter's cold rolling tools

Our clients use oil drilling tools and require strong rotary shouldered connections.

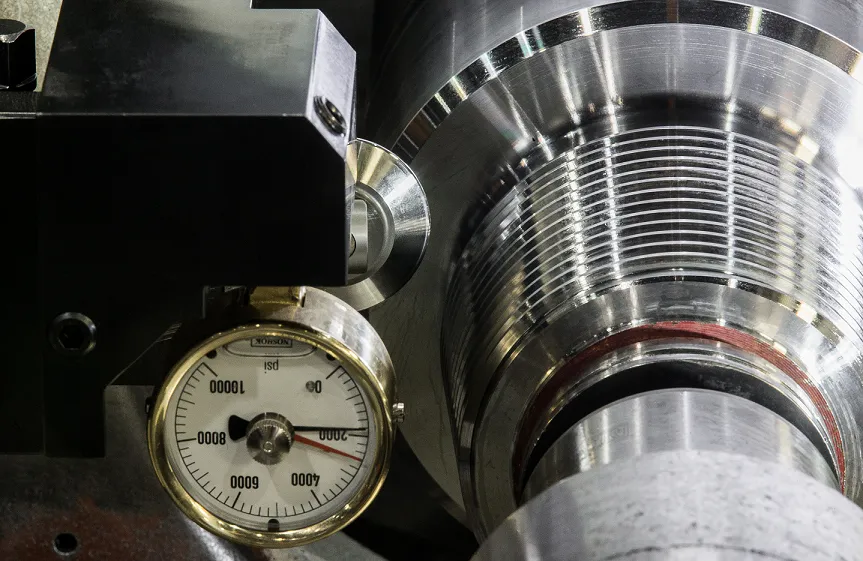

Cold root rolling tools burnish the thread root in rotary shouldered connections, ultimately strengthening the connection and preventing over-stressing and potentially joint failure.

Read the case study below to learn how CJWinter's cold root rolling tools save clients time and resources.

The Problem

CJWinter’s client Wenzel Downhole Tools is a leader in the service and repair of tools used for drilling, particularly for oil and natural gas.

The company has a machine shop located in Edmonton, Alberta. They work very closely with clients in the oil and gas industry, and were facing a period of very high demand from these clients. Before working with CJWinter, the company was outsourcing its cold root rolling work to other machine shops at a rate of $180,000 per year.

Wenzel was facing two major issues: First, the 30-day turnaround time for outsourced parts did not reflect well on the company, and went against their commitment to quality service and prompt delivery. Second, transporting oil and gas drilling components to and from the outsourced machine shops resulted in elevated costs that could have been avoided with in-house machining capacity.

The solution seemed clear: build more internal capacity and stop outsourcing cold rolling work. However, the company had no experience in cold root rolling and could not manage the upfront expenses of acquiring the necessary tools and training employees.

The Solution

They contacted us and were surprised by the time and cost savings that our products could help them achieve, as well as with their relatively simple operation. They told us they were unable to find these two qualities in other cold rolling products.

There are a number of reasons why CJWinter is able to offer a user-friendly product at a reasonable price:

- No external power device is needed to operate our cold root-rolling tools. Every tool can be operated using a socket wrench.

- The internal accumulator, which comes standard on all CJWinter Tools, allows for correct rolling of the critical run out thread with full pressure until the very last scratch.

- Our Error-Proof Loading (EPL) system guarantees that wheels are installed correctly – eliminating an expensive mistake during operation common with other competitive tooling.

- No conversions are necessary: hydraulic pressure and roller force values are 1:1, reducing the possibility for errors and greatly simplifying the rolling process. This feature also ensures the safety of tool operators.

- Our liquid-filled pressure gauges permit post-cycle measurements, rather than measurements during the cycle when moving parts and coolants can restrict proper measurement. This provides safer working conditions for the operator.

Interested in learning more about CJWinter’s products? Contact our team today!

Cold Root Rolling Tools

Wenzel initially purchased two of our tools: the 11070-250-GP and the 11072-A-125-GP, as well as a complete set of wheels for all the connections, both of which can be used to increase fatigue resistance without slowing down the overall machining process.

The 11070-250-GP is part of the CJWinter 11070 Series of Internal Thread (BOX) Bar-Style Tools. All of our tools in this Series are compatible with any CNC lathe.

The 11072-A-125-GP is part of our 11072 Series of External Thread (PIN) Turret Mount Tools. This series of tools is used for cold root rolling pin connections. It has been designed for optimal use in the petroleum industry: burnished threat roots in rotary-shouldered connections ultimately strengthen connections and prevent joint failures. The turret-mounting feature eliminates the need for an intermediate tool holder.

CJWinter engineers visited the client’s site to install both tools and to provide training to the machine operators. Our in-house engineering team maintains contact with the client and is available at any time to provide any support needed.

The Result

Wenzel was very excited about their new cold root-rolling tools and thankful for the support we were able to provide. The tools reduced the shop’s outsourcing expenses significantly, and have also dramatically reduced lead times.

They also appreciated how easily our cold root rolling tools were integrated into their existing manufacturing facility. In fact, our tools combine easily with several common industrial lathes, such as those produced by Weiler, Doosan, Mazak, and more. The nearly effortless operation of the tools ensure employee safety, while simplifying the training process so that you can get started with producing super-strong threaded connections at much higher volumes than with competing tools.

Conclusion

Working with CJWinter was a win-win for all parties involved. Our client benefited from the reduced costs associated with having in-house cold root rolling capabilities, and their customers benefited from faster deliveries, increased the life of the rotary shouldered connection, and reduced down times.

We invite you to contact CJWinter today or view our resources to learn how to safely and cost-effectively integrate cold root rolling into your existing processes.

See Who Else Is Using CJWinter's Technology

Visit Our Customer Locations Map